The importance of XLR cable

XLR cable, also known as XLR cable, occupies an important position in the field of audio and video connection with its unique design of XLR connector. This cable has become an ideal choice for connecting professional audio equipment with its excellent anti-interference ability and stable transmission performance. Whether it is used for the connection between microphone and mixer, mixer and peripheral equipment, or peripheral equipment and power amplifier, XLR cable shows its indispensable importance.

The XLR cable connector is exquisitely designed and contains three contacts: pin, ring and sleeve. These contacts are arranged and connected in a specific way to ensure the accuracy and stability of signal transmission. When making XLR cables, the precise processing of these contacts is crucial, which directly affects the overall performance of the cable.

02

Production process of XLR cable

> Basic knowledge

The XLR cable connector consists of three contacts: Contact 1 is used for grounding (Ground), ensuring the stability and anti-interference ability of the signal; Contact 2 is the hot end (+ level), as the positive pole of the balanced signal, responsible for transmitting the main audio signal; Contact 3 is the cold end (- level), as the negative pole of the balanced signal, together with Contact 2 to form a balanced transmission and suppress external electromagnetic interference.

> Tools and materials

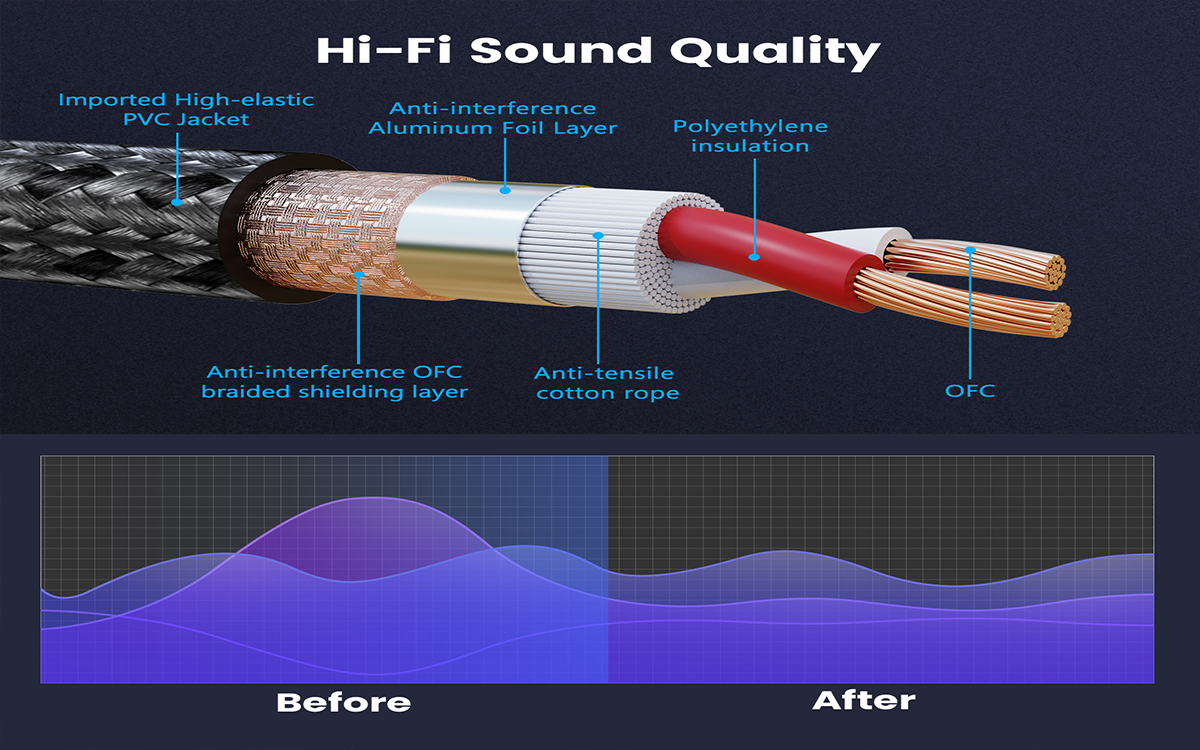

The production of XLR cable requires tools such as electric soldering iron, solder wire, wire stripping pliers, and materials such as three-core audio cable and heat shrink tube. The tools prepared are: electric soldering iron, used to solder wire and XLR head; solder wire, for welding operation. In terms of materials, wire stripping pliers are needed to strip the outer skin and sheath of the wire, and scissors are used to cut the wire and heat shrink tube. In the production process, the three-core audio cable is the core component, which contains two signal wires and one shielding wire, connected to the XLR head. In addition, you need to prepare XLR male and female connectors, that is, one XLR male connector and one XLR female connector, as well as heat shrink tubing to protect the welding points and shielding layer, and use insulating tape to fix and mark the wires.

> Production steps

The steps include stripping, preparing for welding, removing the XLR connector, welding, repeating steps, and heat shrink tubing protection. First, use wire strippers to strip the outer rubber sheath layer at one end of the audio cable, then remove the shielding layer and remove the cotton yarn filler that may exist in it. Put the heat shrink tubing on the ground wire (shielding layer) and tighten it for insulation protection. Tin the copper cores and shielding layer of the wire. Remove a XLR connector, unscrew the bottom cover, remove the wire clip and shell, take out the inner core, and evenly plate a layer of solder on the three welding points of the XLR connector inner core. Fit the bottom cover and wire clip of the XLR connector with the wire and perform welding operations. After welding, place the inner core into the XLR shell, tighten the wire clip, and screw on the bottom cover. Perform the same welding and protection on the other end of the wire.

> Common wiring diagrams

Provide XLR to large three-core and large two-core wiring diagrams. XLR to large three-core wire is a very common wire in daily applications. The wiring method is shown in the conversion of XLR male head to large three-core plug. XLR to large two-core wire, this connection method is an unbalanced connection, one end uses a XLR head, and the other end is equipped with a large two-core head, that is, a TS plug, which is often used for karaoke microphones.

Please note that the actual wiring needs to be adjusted according to the specific situation to ensure the accuracy and stability of the connection.

After completing the above steps, you will successfully make a high-quality XLR cable. Whether in a professional recording studio, a lively performance scene, or a warm home theater, mastering the production skills of XLR cables will bring great convenience and protection to your audio connection work.